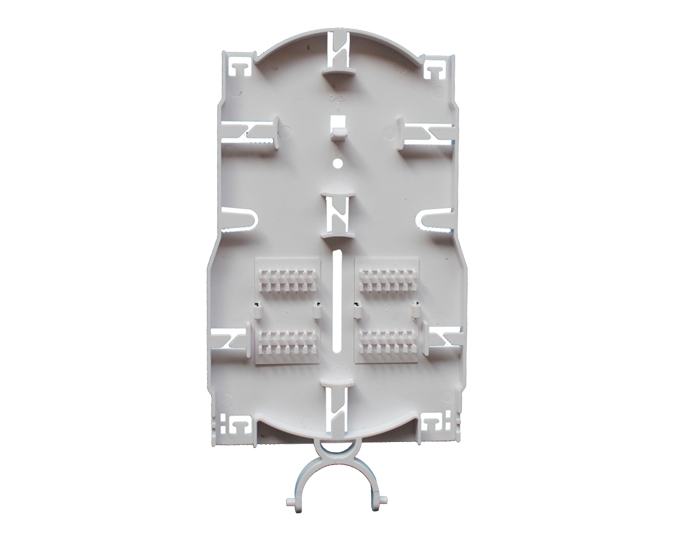

Description:

Fiber Optic Cassette Cleaner intended for use on the exposed ferrules of fiber optic connectors. It is the best non-alcohol cleaning method for various fiber optic terminations which is simply and swiftly used. It provides for cleaning SC /FC/LC/ST/MU/MPO/D4/DIN/E2000 fiber connectors end faces of any male fiber connector. Built with tough ABS resin impregnated with an anti-static cloth, the fiber cleaner box is perfect for both inside and outside plant applications. The anti-static cloth produces a rustic fiber tip and minimizes the attraction of contaminants.

Fiber Optic Cassette Cleaner uses superfine textile tape, it easily and efficiently Times the fiber end face without nicking or scratching the surface or leaving alcohol bloom in order to maintain good quality optical connections. Cassette tapes are available for replacement after 500+ cleaning operations to ensure low cleaning costs.

Features:

Suitable for cleaning the ferrule end-faces of SC/FC/LC/ST/MU/MPO/D4/DIN/E2000 connectors

Use of non-alcohol special microfiber straps.

Easy to replace the tape, no pollutions.

Effectively clean all kinds of dust, oil, and debris.

Friendly using, efficient cleaning.

Well handled and antistatic.

Low cost per clean over 500 cleanings per unit

Cleanliness Can Reach 90%.

Friendly using, efficient cleaning.

Product Specification:

| Model Number | Fiber Optic Cassette Cleaner | Color | Dark Blue |

| Function/Handling type | One-Push | Dimensions (HxWxD) | 40mm x82mm x138mm |

| Life | >500times | Weight | 0.3 kg |

| Connector | LC/SC/FC/ST/MTP/MPO/D4/DIN Connector | Polish type | PC/UPC/APC |

| Relative Humidity | ≤ 85% (30°) | Air Pressure | 70Kpa~106Kpa |

| Cleaning Method | Dry (Cleaning the Zirconia ferrule end face with cleaning cloth, with no chemical or solvent). | ||

| Working Environment | 0℃~+70℃ | ||

Applications:

1.Fiber network panels and assemblies.

2.Outdoor FTTX applications.

3.Cable assembly production facility.

4.Testing laboratories.

5.For clean SC/FC/LC/ST/MU/MPO/D4/DIN/E2000 Connectors & Adaptors.